الشركة المصنعة للجهاز مصغرة مصنع الاسمنت

Modernizing cement manufacturing in China leads to

2022年11月17日 The cement manufacturing process mainly includes four steps: resource extraction, raw material preparation, clinker calcination, cement grinding 17, 18, and Resources Get quote Improve product quality, maximize resources, gain efficiencies Keep cement manufacturing operations running efficiently, safely, and profitably with applied Cement Manufacturing Thermo Fisher Scientific US

Cement Production an overview ScienceDirect Topics

1 Introduction Cement production is a thermal energy intensive process, which requires heating solid particles up to 1450°C and cooling it down The process generates hot and Cement Production Machinery 249,637 products found from 9,601 Cement Production Machinery manufacturers suppliers Product List ; Supplier List; View: List ViewChina Cement Production Machinery, Cement Production Machinery

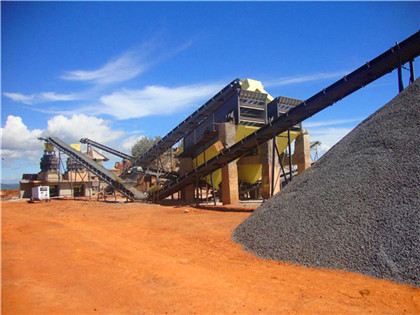

China Cement Production Plant, Cement Production Plant

China Cement Production Plant manufacturers Select 2023 high quality Cement Production Plant products in best price from certified Chinese Construction Equipment, Sand Making custom aluminum casting rotary hammer steel structure for building pvc production line carbonization furnace gypsum board making machine can making machinery We Cement Making Machinery, wholesale Cement Making

Cement production machinery price Manufacturers

cement production machinery price manufacturers/supplier, China cement production machinery price manufacturer factory list, find best price in Chinese cement production Cement Production Machinery Factory Select 2023 high quality Cement Production Machinery Factory products in best price from certified Chinese Machinery Production Cement Production Machinery Factory, Cement Production Machinery

Cement Production Machinery Price, 2023 Cement Production Machinery

Cement Production Machinery Price Select 2023 high quality Cement Production Machinery Price products in best price from certified Chinese Machinery Production With the rapid development of the economy for 20 years, mature cement production line technology is at the top level in the world Through the efforts of all staff for years, China China Cement Machinery Manufacturer, Cement Machine,

Cement raw materials production Cement Plant, Cement Equipment

We provide customers with a variety of cement plant equipment and optimize the combination of various types of cement grinding مطحنة to meet the needs of different processes cement ball مطحنة Feeding size: ≤25mm Capacity: 065615t/h vertical cement مطحنة Feeding size: ≤1100mm Capacity: 5200m³/h raymond مطحنة 2020年8月25日 There are three steps of the hightemperature system: Drying or preheating, calcining, and sintering The calcining is the core part of the clinker production; the raw meal is weighed and sent into preheater and cement kiln to process clinker Grate cooler helps to cooler clinker, the cooled clinker is sent to the cement silo for storageCement Production Process Cement Manufacturing Process AGICO CEMENT

雅思写作小作文范文 雅思写作流程图flow chart 水泥

2019年2月21日 雅思写作小作文范文 The first diagram illustrates the process of cement manufacture, and the second diagram shows the materials that go into the production of concrete 张图表说明了水泥 2023年3月30日 Machinery procured for the cement production When discussing the costs of establishing a cement production plant, it is important to consider the costs for machinery and equipment Modern, stateoftheart cement production requires a variety of machines and equipment that are capable of reliably and consistently producing highquality cementDiscover the True Costs of Starting a Cement Manufacturing

Modernizing cement manufacturing in China leads to

2022年11月17日 NSP rotary kilns started to account for than 10% of the market share in 2001, and China’s national cement production peaked in 2014 Therefore, 2001 and 2014 are selected as typical yearsDouble MultiKiln Cement Plant, Automation Grade: Automatic, Capacity: 500 Tpd 5000 Tpd ₹ 99 Lakh/ Piece Get Latest Price Size/Dimension: Customized Capacity: 500 TPD 5000 TPD Automation Grade: Automatic Weight: 10000 Ton to 50000 Ton Usage/Application: Cement ManufacturingCement Machinery Cement Making Machine Latest Price,

Portland Pozzolana Cement Manufacturing Plant PPC Cement Production

Portland pozzolana cement (PPC) is a type of ecofriendly cement which is mainly made of ordinary portland cement clinkers and pozzolanic materials (such as fly ash, calcined clay, etc) Generally, the constituent of pozzolanic materials in Portland pozzolana cement is 10% ~ 25% by mass percentage Fly ash is the main ash discharged from the2021年6月4日 5000 Tons/Day New Type Dry Process Cement Production Line Pengfei 5000t/d dry process cement production line is excellent in saving energy It adopts various high efficient cement equipment and devices It is designed with a smooth and tight process flowe try to reduce production process and save transport costCement Production Line,Cement Machine,Rotary Kiln,Cement Equipment

Graph Writing # 102 Stages and equipment used in the cement

2022年8月4日 On the final stage, the cement is packed and ready for commercial use Production of concrete is done in a machine called a concrete mixer The process mixes 15% cement, 10% water, 25% grains of sand and 50% gravel (small stones) All those raw materials are poured into the concrete mixer which continuously rotates to form concrete1 天前 News and commentaries All news and commentaries Fossil fuels continued to be the main source of thermal energy for the sector (90% share) in 2022, followed by bioenergy and renewable waste (4%) and nonrenewable waste (4%) The adoption of low carbon fuels is key to reduce the share of fossil fuels to 79% and nonrenewable waste to 3% by 2030Cement IEA International Energy Agency

The Cement Manufacturing Process Thermo

2015年8月20日 Domestic cement production has been increasing steadily, from 664 مطحنة ion tons in 2010 to about 805 مطحنة ion tons of Portland cement in 2014 according to the US Geological Survey 2015 Cement Mineral Cement Plant Machinery Cement Plant Equipment Cement Production Plant Cement Mixing Plant Marble Planter Granite Planter Concrete Batch Plant Grinding Media Ball Rubber Conveyor Belt 3 Phase Electric Motor Cement Mixer Aggregate Concrete Mixing Plant Mixed Hzs120 High Performance Batching PlantsChina Cement Plant, Cement Plant Manufacturers, Suppliers,

Technological Energy Efficiency Improvements in

2021年3月30日 Figure 1 Cement production process The colored boxes show the sequential operations, while the white boxes summarize the process machinery Based on the water content of the raw materials, the cement manufacturing process can be divided into four categories: dry, semidry, semiwet, and wet [9] Since cementAGICO dry process cement production line comprehensively adopts the IT technology, multifunction grinding system, newtype wearresisting and heatresisting materials, mechanical powder conveying device, and some other modern technologies to realize quality cement production It has the characteristic of energy saving, high efficiency, environmental Cement Production Line Cement Manufacturing Plant AGICO Cement

Cement Manufacturing Equipment for Sale AGICO Cement Machinery

Cement Plant 700 ~ 2000tpd; Cement Plant 2500~7000tpd; Cement Types Menu Toggle OPC Manufacturing Plant; PPC Manufacturing Plant; White Cement Manufacturing; Quick Setting Cement Production; Others Menu Toggle Cement Plant Upgrade; Cement Grinding Plant Hot Sale; Modular Grinding Plant; Active Lime Production Line; Activated Carbon A cement مطحنة is just a general term for clinker grinding مطحنة It is a kind of grinding equipment that used to grind the calcined cement clinker then make them reach the particle fineness requirement of the finished cement product It is the core equipment of the last step in the cement production process The cement مطحنة we usually used inCement Manufacturing Machine Cement Making Machine Cement

IELTS Task 1 Process Cement and Concrete Production

2015年4月14日 Below is a sample band 9 answer to a process task 1 question on concrete production Source: Cambridge English IELTS Past Papers Question– The diagrams below show the stages and equipment used in the cementmaking process, and how cement is used to produce concrete for building purposes AnswerCement Production Cement production is an energy intensive industrial process that requires heat to be supplied at high temperature levels under the constraints of gassolid heat exchange phenomena and the kinetics of chemical reactions which were later replaced by rotary kilns as standard equipment worldwide Today ‘s annual globalCement Production an overview ScienceDirect Topics

Cement Plant EPC Service Equipment Supply AGICO Cement

The Leading Cement Plant Supplier from China Since 1997, AGICO Cement and its subsidiary LCDRI (Luoyang Cement Engineering Development Research Institute) have never stopped the research in the field of cement production technology and cement equipment design Over the past 20 years, our engineers and construction teams have AAC Block Production Line,EPS Cement Wall Panel Machine, Concrete Block Making Machine, Cement Pipe Machine, Cement Tile Machine Mgmt Certification: ISO9001:2015Cement production machinery price Manufacturers